Biofuels are fuels produced from organic material, as different from fossil fuels such as petroleum or coal. The fossil fuels are non-renewable. In particular, petroleum on which the entire transportation industry is based, is expected to run out within next 30 years. There are stepped up efforts round the world to find alternative energy sources. Biofuels, as a renewable energy source, has made some headway, meeting some 2.7 percent of the global energy usage in 2010. This is projected to rise to 25 percent by the year 2050.

Biofuels can be broadly classified in three categories solid, liquid, and gas. Of these, the liquid form is getting the most attention due to the possibility of substitution for petroleum usage in transport vehicles. The next in important alternative source of energy is the bio gas and then the solid form. The developments in all three forms, holds the promise of biofuels emerging as an alternative energy source, in the coming years.

1. Liquid Biofuels

Liquid biofuels are primarily used as additives to the liquid petroleum based fuels. The substitution is expected to be progressively raised in percentage as experience is gained with the blended fuels. In addition, the engine manufacturers are working on modifications to permit the use of higher percentage blends.

a. Bio-ethanol

Bio-ethanol has been the earliest biofuel introduced and has already been widely used in Brazil and USA. Ethanol is alcohol, obtained by fermenting sugar and starch obtained from plants. The process used is the same, as is used for brewing alcoholic beverages. In Brazil ethanol is produced from sugar beet and in the US from corn. Large acres of farmland were converted to growing these crops for ethanol production and farmers were given government subsidies to grow these biofuel crops. Some additives like methanol or gasoline were added to the ethanol to make in inedible. This ethanol has been blended with gasoline to the extent of 10-15 percent as a petroleum substitute. Ethanol addition adds to the octane number of the fuel and also reduces the vehicle emissions. This widespread conversion of farmlands from food to fuel production, however, drove up corn and sugar prices around the world and attracted criticism especially in some famine years.

b. Second-generation bio-ethanol

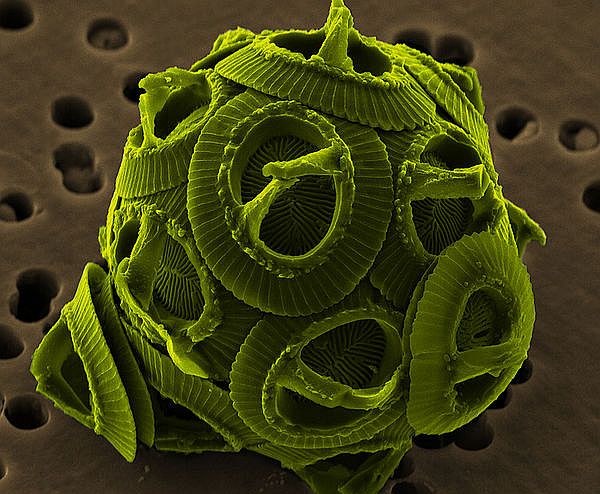

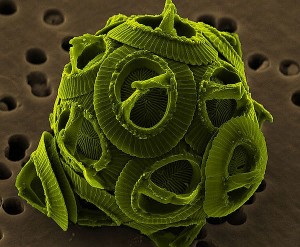

Scientists have found that in the bio-ethanol production process previously followed, only the corn or the sugar beet crop was used for fuel production where the rest of the plant became a waste product. This led to the discovery of the cellulosic fermentation process where the stalk and leaves of various plants that contain cellulosic material could also be converted to ethanol. This discovery enormously improved the ethanol yield per acre and since nonedible plants could also be used, the issue of food versus fuel production was sought to be addressed. Cellulosic fermentation takes place at high temperatures, it requires energy. In addition it uses enzymes that are able to withstand the high temperatures.The second generation bio-ethanol technology is supplanting the previous bio-ethanol production process. Algae is also used in bio-ethanol production.

c. Bio diesel

Bio diesel is made from vegetable oils and animal fats, including recycled oils and fats. The use of recycled oils and fats from the food industry is particularly attractive as it addresses the environmental disposal issues of used fats. A 5 percent blending of bio diesel with petroleum based diesel fuel has been used for a number of years in Europe. This blend could be used in cars without any modification to the engines. Higher blends would need changes to the engine design and to some of the materials used in the fuel line.

d. Green diesel

Green diesel is made from various vegetable oils like canola, algae, and jatropha, which are non-edible. Green diesel is made by fractional distillation and has been used widely in Ireland. Some of the crops for green diesel production can be grown in wastelands where other crops are not grown. These crops provide a productive use for such wastelands.

2. Gaseous Biofuels

The gaseous biofuels aim to supplement or supplant petroleum based gases in domestic heating, cooking, and certain industrial applications.

a. Landfill gas

Landfill gas is primarily methane gas that is emitted by the natural decay of bio-degradable garbage in dumps.The decay is caused by microbes and bacteria in the presence of moisture and sunlight. In the past, these gases went into the atmosphere.These gases are now being collected and piped into city gas distribution systems.The municipal waste collection process has also been improved to segregate the city wastes into bio-degradable wastes and other recyclable wastes like plastics and metals. This has led to improved processes of waste disposal from cities and enhanced recovery of methane gas.

b. Anaerobic Digesters

Anaerobic Digesters are closed tanks, where microbes are used to breakdown waste material like paper, plant, and grass cuttings leftover food and sewage sludge. A family of microbes and bacteria are “seeded” to breakdown different components of the waste material like carbohydrates, starch, and sugar. The tanks are closed and evacuated to exclude oxygen. The microbes draw the oxygen needed for reproduction from the waste material itself, speeding up the disintegration process. This digesting process, yields a mixture of methane and carbon dioxide and can be piped out as fuel gas.The digested material left after the evolution of gas, can be used as fertilizer or can be made into briquettes and used as solid fuel. Such digesters are widely used in many cities around the world as a pretreatment for reducing the volume of garbage into a landfill. It is also commonly used in farms and isolated communities without municipal garbage collection and disposal services.

c. Syngas

Syngas stands for ’synthesis gas’ and is a mixture of carbon monoxide and hydrogen. Syngas is produced by partial combustion of biomass in an atmosphere containing steam. A limited quantity of coal is used for combustion. The partial combustion results in the carbon from the bio-mass absorbing oxygen from the steam, to produce carbon monoxide and hydrogen. This syngas is piped out to be used as fuel. One company that has installed several syngas plants in Norway, Germany, and UK is Energos. These plants use municipal waste to produce energy.

3. Solid Biofuels

Solid Biofuels, as the name suggests, are in solid form. Firewood is the oldest form of a solid biofuel. In the rural countryside in India and other tropical countries, dried cow dung has been used as a biofuel. Now attempts are being made to convert agricultural waste products into biofuels.

a. Wood pellets

These are made from sawdust which is a waste material from the wood industry. Sawdust is passed through a hammer mill for compaction into a dough-like mass and extruded under high pressure into pellets, that are typically 6 mm in diameter and 8 mm in length. The extrusion process causes the lignin in the sawdust to become plastic to bind the saw dust together. The extrusion process also elevates the temperature of the pellet and dries it, to a moisture content less than 10%. The low moisture helps the wood pellet to burn cleanly. These wood pellets are used as the fuel in water heaters for domestic heating in many countries. Sweden, which is a wood industry center uses over 1.5 million tonnes of wood pellets as fuel.

b. Peanut shells

In parts of sub-Saharan Africa and in parts of India where peanuts are a major crop, the peanut shells are used as a solid biofuel. The shells need a binder to convert them into a manageable fuel. In India, the peanut shells use bitumen tar as the binder. The tar is melted by setting it alight and peanut shells stirred into it.Then the fire is put out by water. The molten tar hardens and binds the peanut shells that can then be used in a coal burning boiler or even in a domestic coal burning stove.

In parts of Africa, tapioca paste has been used as the binder, followed by drying in the sun.

c. Mayon Turbo Stove for using rice husk as bio-fuel

In many parts of the world,rice is the staple food and many millions of tonnes are produced. The rice husk produced from milling is a major agricultural waste.The Canadian company Mayon, has designed a stove that uses rice husk or other waste products like peanut shells as the fuel.The stove is designed with ingenious air injectors to ensure smokeless burning of the husk.

d. Grass and weeds as solid bio-fuels

In place of agricultural waste products being converted to solid bio-fuel,many companies are beginning to grow crops specifically intended as fuel.Miscanthus is a perennial grass growing in many parts of the world, that is not eaten by grazing animals. These plants are now being commercially grown for bio-fuel production.The leaves of the grass can be used for bio-ethanol production and the stem and stalks are converted into briquettes to be used as solid fuel.The yield per acre of bio-fuel from this grass is said to be 2.5 times the bio-fuel yield from corn farming. A company named Aloterra Energy already has a demonstration form operating in Ohio. The use of bio-fuels gives the world an alternative energy source to fossil based fuels and this industry looks to develop further as new technologies emerge to optimize the use of unconventional materials as bio-fuels.

Follow

Follow