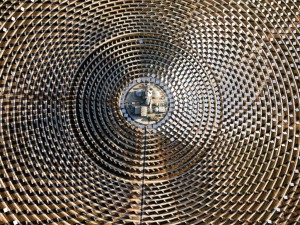

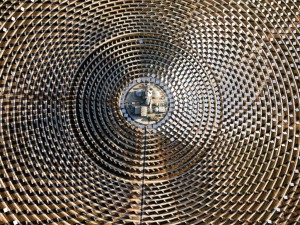

Gemasolar, the world’s first commercial high-temperature solar power plant, is expected to be able to supply energy to the grid based on demand, regardless of whether there is constant solar radiation

Gemasolar, the world’s first commercial high-temperature solar power plant, is expected to be able to supply energy to the grid based on demand, regardless of whether there is constant solar radiation

At the end of 2010 workers put the final touches on an enormous structure in Southern Spain; a concrete tower, 140 meters tall, surrounded by a field of 2,650 large mirrors, each roughly 10 meters by 10 meters, covering a total of 18 hectares. The 19.9 MW solar tower plant, surrounded by semi-arid cropland in the province of Seville, Spain, may be remembered as the first of a design that is replicated across multiple continents, transforming solar power from an “alternative” to a mainstream technology.

Construction of the Gemasolar plant. Torresol Energy Investment S.A.

It is not the field of mirrors or central receiver that makes this plant groundbreaking, but rather what passes through the receiver, and fills the 14 meter high, 36 meter wide tanks at the base of the plant.

Molten salt tanks and turbine building at the base of the Gemasolar plant. Image SENER Group

The Gemasolar plant is the first commercial-scale plant to use molten salts, heated to a temperature of 565 degrees Centigrade, as a thermal receiver and to provide 15 hours of molten salt storage.

The implication of this technology is enormous. The Gemasolar plant not only supplies power during sunny periods, but as needed, up to 24 hours per day, without the considerable expense of battery storage.

It is for this reason that the Gemasolar concentrating solar power (CSP) plant, owned by Torresol Energy Investment S.A. (Getxo, Spain), a joint venture of SENER Group (Getxo, Spain) and Masdar (Abu Dhabi, U.A.E.), is Solar Server’s June 2010 solar energy system of the month.

Solar and intermittency

A central limitation of solar technologies has been that they typically only deliver power when the sun is shining. This is not entirely problematic, as in many regions daily increases in electricity demand is similar to the output of solar power.

Yet this does limit the maximum amount of solar that can be deployed without additional storage, which can be prohibitively expensive, or deploying additional “on-demand” generation, usually natural gas.

More on this subject can be found in Solar Server’s report on energy storage and solar power

However, due to the use of molten salt storage for overnight periods, Torresol Energy’s Gemasolar plant is the first solar plant in the world which can supply a flexible amount of power on demand 24 hours per day, similar to a natural gas plant.

Graph of energy production at the Gemasolar plant. Image courtesy of Torresol Energy Investment S.A.

The time comes for CSP

Though a large number of the world’s operational CSP plants have been built in the last five years, the idea is not new. The U.S. Department of Energy (DOE) built the first CSP plant, a solar tower design similar to Gemasolar, in California in 1981. However, after a series of plants were built in California’s Mojave Desert, the technology was largely abandoned for more than a decade.

In the beginning of the 21st century a new interest in solar technology led a number of companies to investigate CSP; however, few new plants were built until the passage of revisions to Spain’s feed-in tariff in 2007, which brought a flood of new CSP plants. Today Spain hosts the world’s largest operational CSP capacity.

SENER Ingeniería & Sistemas, the engineering arm of the SENER Group, became involved of concentrating solar power in 2001, providing construction services for the Solar Tres CSP plant.

Torresol Energy and the molten salt concept

SENER also provided engineering, procurement and construction (EPC) services for the Andasol 1 plant, a parabolic trough plant which was the first CSP plant to use molten salt storage when commissioned in November 2008.

In 2006 the company launched project Gemasolar, investigating the possibility of thermal storage with CSP. During that year, SENER built an experimental unit in the Almeria Solar Platform to test the solar tower design with a molten salt receiver.

In March 2008, SENER and Masdar formed Torresol Energy to advance CSP plants globally, and SENER transferred Project Gemasolar to the new company.

SENER provides technology for Torresol Energy, whose purpose is to develop molten salt CSP globally, starting with the Gemasolar plant.

Construction of Gemasolar: making the idea real

After signing a project contract in late 2008, Torresol Energy began work on the Gemasolar plant.

The Gemasolar plant under construction in 2009, before the installation of the field of heliostats

Image Credit: Torresol Energy Investment S.A.

SENER was responsible for construction, a process that took a total of 29 months, including seven months to assemble the field of mirrors, (heliostats). The central tower was constructed using a sliding form casing.

“Obviously, constructing 2500 mobile heliostats, each heliostat having 110 m2 of silvered glass, a 140 m concrete tower, tanks to keep 8500 metric tons of molten salts, etc., is not an easy task,” notes Torresol Technical Director of Operations and Maintenance Santiago Arias Alonso.

“But SENER has achieved a very high experience in designing, purchasing, constructing and commissioning all the components.”

Torresol states that the project was financed with a EUR 171 million (USD 247 million) loan by several private banks, led by the Popular Bank.

Commissioning: lighting up Andalusia

In early 2011, Gemasolar began running on a test basis, and was officially commissioned on May 1st, 2011.

Electricity generated by the plant is sent via high tension line to a local substation, on an electric grid owned by Endesa S.A. (Madrid, Spain), for distribution mainly in Spain’s Andalusia region.

Torresol Energy notes that the daily profile of Spanish electricity demand has two peaks, with the second falling between 8 PM in the winter and 10 PM in the summer, after the sun has set. Due to its molten salt storage, the Gemasolar plant can supply power to meet both peaks.

Details of molten salt and a tower design at Gemasolar

While SENER is involved in the construction of 15 CSP plants, the Gemasolar plant is its first to use a heat storage system at greater than 560 degrees centigrade.

The system uses a total of 8,500 tons of sodium and potassium nitrate salts, which are kept in a molten state. Torresol Energy states that the salt absorbs 95% of the heat energy from sunlight in the central receiver, after which the salts are sent to a storage tank, and a portion is used to generate steam via a heat exchanger.

The direct heating of the molten salt is different from previous designs, such as the Andasol 1 plant, based on a parabolic trough design, which use thermal oil as a receiver, and then transfer the heat to the molten salt solution. Torresol Energy notes the efficiency advantage of removing one step of heat transfer.

Advantages and efficiencies of molten salt CSP

Torresol Energy states that tower power CSP systems offer advantages over parabolic trough CSP, noting that Gemasolar includes no mobile piping system, no swivel joints, no thermal oil and no potential fire or spillage risks. Additionally, the concentration of fluids in a small area leads to lower thermal losses and maintenance costs.

Torresol Energy also notes technical advantages of the storage system, stating that short bursts of power, as are caused by the passing of clouds in systems without storage, shorten the working life of turbines. The company also states that incorporating the heat storage system reduces load variations and increases turbine efficiency.

Because a large amount of the molten salt is stored, the output capacity of the turbine is smaller than would be expected from a plant of its size. The thermal receiver has a 120 MW-thermal capacity, however the plant uses a 19.9 MW turbine. Torresol Energy expects the plant to produce 110,000 MWh of electricity annually.

The future: molten salt goes global?

Torresol Energy officials say that the idea of molten salt storage has definitely caught on in the CSP industry.

“Four years ago, when I was working at SENER in the molten salt storage system for Andasol 1, all our competitors considered that ‘we were nuts’ by trying to store and deliver the energy,” recalls Santiago Arias Alonso. “Currently, all our competitors are testing or trying to design molten salt storage systems.”

For its part, Torresol Energy seeks to build more plants with molten salt storage in multiple locations around the world. The company is currently developing two molten salt storage parabolic trough CSP plants, the Valle 1 and Valle 2, in Spain.

If solar and other renewable energy technologies are to replace fossil fuels and nuclear power, they must be able to generate power 24 hours per day without requiring overly expensive storage. The Gemasolar plant shows that this can be done at a commercial scale. The future is here.