Liquid Metal Battery Corporation (LMBC) is a Boston-area startup pursuing an liquid metal battery technology. According to this Greentech Media piece, Don Sadoway of MIT is the inventor of LMBC’s core technology.

Sadoway is a named co-inventor on two related patent applications, U.S. Application Publication Nos. 2011/0014503 (’503 Application) and 2011/0014505 (’505 Application) describing and claiming batteries having liquid metal electrodes.

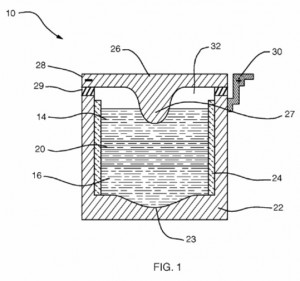

The ’503 Application is entitled “Alkaline earth metal ion battery” and is directed to an alkaline earth metal ion energy storage cell (10) which contains three liquid constituents: two liquid electrodes and a liquid electrolyte.

More particularly, the cell (10) houses a molten metal body (14) that serves as a negative electrode, an electronically conductive liquid alloy body (16) that serves as a positive electrode, and an intervening ionically conductive electrolyte (20).

According to the ’503 Application, calcium or magnesium is used in the liquid electrodes (14, 16) because these elements generate relatively high voltage, are safe to handle and are relatively inexpensive.

An electronically conductive container (22) houses the liquid constituents, including an electronically conductive lid (26). An insulating inner sheath (24) prevents shorting between the negative and positive electrode (14, 16), and an insulative seal (29) confines molten constituents and vapors to the container (22).

A portion of the lid (26) in contact with the negative electrode (14) acts as a negative current collector (27) such that electrons pass between the negative electrode (14) and an external source or sink by way of a negative terminal.

Similarly, a portion of the container (22) is in contact with the positive electrode (16) and functions as a positive current collector (23), through which electrons pass between the positive electrode (16) and the external source or sink by way of a positive terminal (30).

The ’505 Application, entitled “Liquid electrode battery,” is a continuation-in-part of the ’503 Application, which means it claims priority to the ’503 Application and has some common disclosure as well as some new material.

The ’505 Application adds certain improvements to the liquid metal battery, such as a circulation producer including thermal management devices to provide a heat transfer path so heat can be conducted away from the liquid constituents (14, 16, 20) of the battery.

According to the ’503 and ’505 Applications, the use of liquid electrodes provides the advantage of higher current density:

The use of electronically conductive liquids for electrodes 14 and 16 with a liquid electrolyte 20 facilitates facile oxidation and reduction of the active alkaline metal and its cation at the electrodes 14 and 16. The electronic conductivity of the liquid electrodes promotes high current density during operation of the cell 10 by enabling electron-transfer reactions to occur at sites over entire liquid electrode-electrolyte interfaces rather than being limited to triple-phase intersections. Furthermore, because reactions at both electrodes occur entirely in the liquid state, the reaction kinetics are not throttled by the nucleation of distinct product phases. Thus, the cell constituents are consistent with extremely high current densities…

Sadoway told GTM that the all-liquid configuration is self-assembling and should be scalable for large-scale electrical grid applications at relatively low cost.

Source: cleantechies

Follow

Follow